-

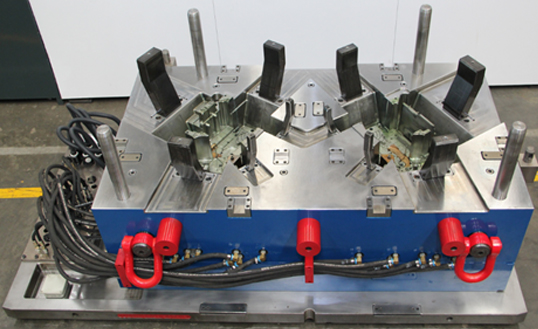

Product and Mould Challenges

- Mould quality at par with European standards of performance and cycle time

- Large number of critical dimensional requirements with extremely low tolerance levels

- Low general wall thickness - 1.6 mm

- Fast cycle time despite multiple and complex mechanisms on both halves

- TAT of 110 days to T1

-

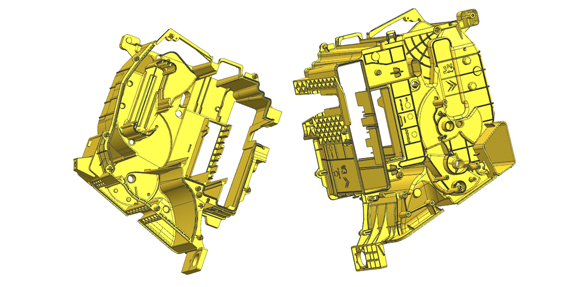

DESIGN & CONSTRUCTION

- With CAE analysis on Mould flow, introduction of conformal cooling through 3D Printed inserts, shorter cycle time was achieved

- Mould design based on mechanically operated sliders and lifters in place of hydraulics, in order to further optimize cycle time and established at 28 secs

- Ease of mould maintenance due to front mounted design schemes for various inserts