40 years of developmental and components

manufacturing experience provided us the exposure in

understanding the automotive product requirements closely

working with OEMs.

We used this legacy as a platform to offer component design and engineering solutions as part of our services through an in-house product engineering centre integrated to our tool shop.

B SURFACE GENERATION

Benchmarking

We follow OEM’s Benchmarking Data to check:

- Thickness Analysis

- Feature Analysis

- Raw Material Study

- Gap & Flushness Study

- Regulatory Requirements

Improvement in Design

We work on:

- Assembly & Packaging Study

- Gap & Flushness Study

- Split Line Definition Study

- Tooling Issues Affecting Styling

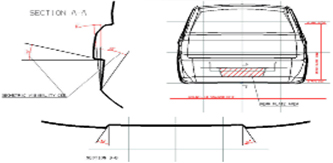

B Surface Development

- Develop CAD from Master Section.

- Detailed Part Design

- Mounting Position Plans

- Proto Build

- Release Process

TURNKEY SOLUTIONS ON PRODUCT ENGINEERING & TOOLING SOLUTIONS

Product Feasibility

Process Feasibility

Tool

Feasibility

Assembly Feasibility

CAE VALIDATION

-

Static & Non Static Linear

Static & Non Static Linear -

Model Analysis

Model Analysis -

Pressure Analysis

Pressure Analysis -

Thermal Analysis

Thermal Analysis -

Mould Flow Analysis

Mould Flow Analysis

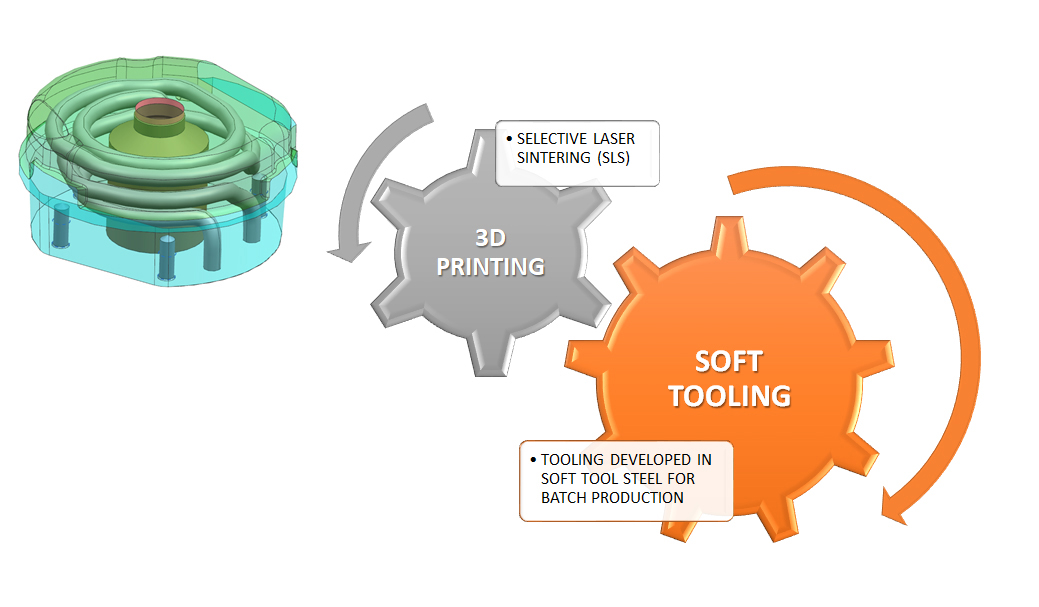

PROTOTYPING: SOFT TOOLING /3D PRINTING